RFID technology has been widely used in the field of logistics and warehousing. RFID warehouse solutions simplifies the complicated workflow of the warehouse and improves work efficiency. The feature of RFID technology is non-contact high-speed identification. The RFID warehouse management system can also identify multiple RF tags and high-speed mobile RF tags simultaneously, providing accurate data for logistics RFID warehouse management.

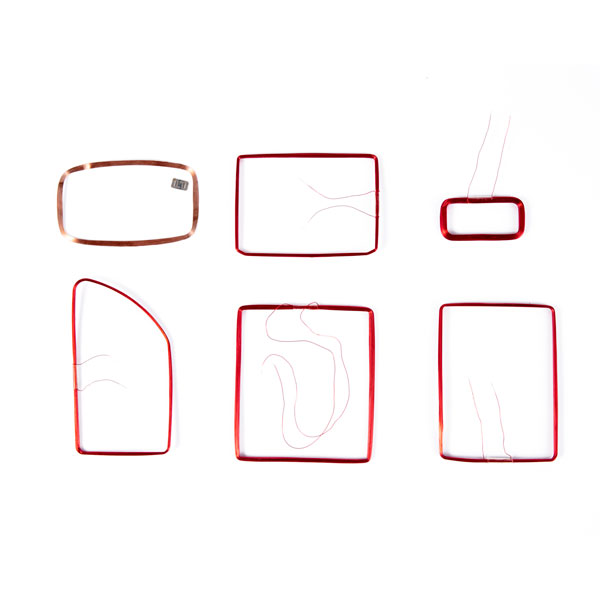

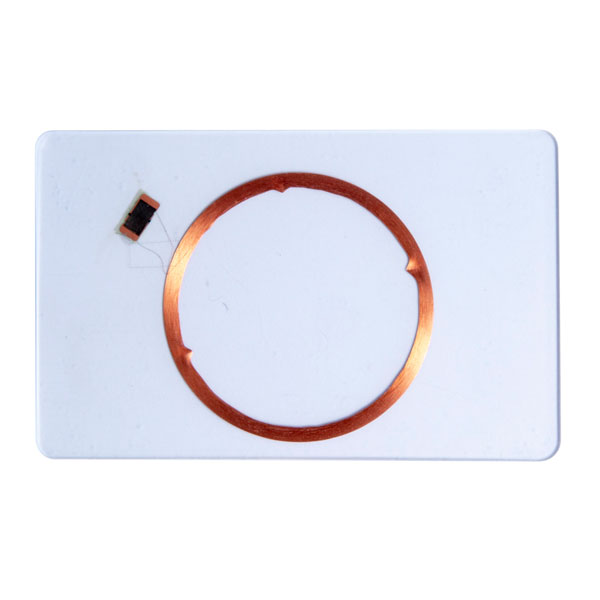

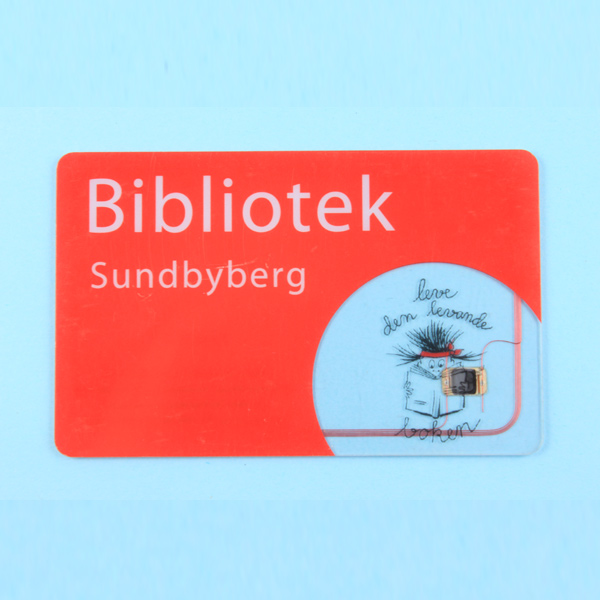

STAR TREND customizes RFID tags from LF, HF to UHF for various operating frequencies to meet the needs of warehouse RFID system to track and locate goods.

STAR TREND customizes RFID tags from LF, HF to UHF for various operating frequencies to meet the needs of warehouse RFID system to track and locate goods.

Benefits of RFID in Supply Chain Management

Greatly improve the speed of goods in and out of the warehouse. Since the RFID tags can realize non-contact, batch reading of the whole box, time, manpower, material and financial resources are saved, and work efficiency is improved.

RFID realizes automatic entry and exit. With hand-held RFID readers can read and write distances up to 12 meters compared with traditional fixed readers which only can read distance to 2-5 meters. RFID warehouse solutions effectively solves the problem of manually scanning the bar code in the past for bar code storage, realizes automatic entry and exit, and greatly improves the labor cost of the warehouse and the efficiency of the forklift.

Reduce inventory time and quickly understand the inventory situation. The warehouse manager only needs to scan the goods with a handhold reader, and the inventory information is uploaded to the host system for comparison to understand the specific situation of the entire inventory. RFID technology in supply chain management can increase the inventory accuracy rate from 62% to more than 95%. In the past, when bar codes were used to count goods, only 200 pieces were counted in one hour. But 5,000 pieces would be counted in one hour after using RFID tags.

RFID can adapt to harsh environments since the radio communication enables it to be used in dust, petroleum and other highly polluted and radioactive environments, with a life span of more than 10 years (100,000 years of reading and writing); traditional bar code carrier label paper is easily contaminated. In addition, because the bar code is attached to the plastic bag or the outer packaging carton, it is particularly easy to break; RFID tags are used to store data in the chip, which can prevent pollution, having anti-pollution and durability.

How dose RFID Tags Warehouse Management Works?

1. RFID tags

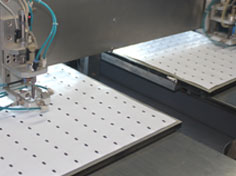

By issuing RFID tags for each pallet and storage location in the warehouse with various special equipment, it can realize the automatic identification of pallet and goods storage information, which greatly help the user to manage inventory goods.

At the same time, through the RFID tag binding to the goods, it can accurately distinguish the actual management problems such as batch, model, product name, warehousing time, supplier, status, etc. The management and control is more in line with modern management needs.

2. Receiving link

Daily receiving tasks can be automatically synchronized to RFID handheld devices, and you can know the details of the tasks without paper receipts. The receipt data does not need to be recorded manually, and the system automatically collects and counts to ensure the accuracy of the receipt data. After the goods are put into the warehouse, the system will automatically update the in-stock inventory quantity, and the documents will also become completed.

3. Shelf link

After the RFID warehouse management system is integrated with the RFID forklift, the shelf tasks can be issued to the RFID forklift for execution. The RFID forklift automatically scans the pallet, displays the pallet's cargo information and warehousing information, submits the storage location of the cargo in real time, and increases the inventory on the shelf.

4. Picking link

The system will automatically optimize the picking walking path. No need to walk back and forth, just one walk to pick up the goods. RFID forklifts scan RFID pallet tags to quickly verify the information of outbound goods, and can perform first-in-first-out verification to improve inventory turnover. After the outbound is completed, the outbound inventory is automatically reduced.

5. Inventory link

There is no need for paper inventory receipts, and the RFID mobile working platform can wirelessly check the RFID based warehouse management system receipts online. There is no need to manually record the inventory data information, since the system supports on-site operation records. The inventory accuracy reaches the location level and the pallet level, making the inventory easier to implement and carry out; supporting the inventory and the in and out business of warehouse at the same time. Combined with the use of RFID forklifts, the inventory speed is faster, and the inventory difference data is automatically summarized.

Related RFID Products for Logistics & Storage